Using the reference clock to realize serial communication data recovery of Cyclone10LP devices

In the non-source synchronous low-speed serial data communication scenario, the clock frequency of the communication counterpart may be biased, which may cause the data receiving end to be unable to accurately sample. In this case, the SOFT-CDR and DPA functions in the high-speed transceiver or LVDS serdes of high-end Altera devices can effectively solve this problem.

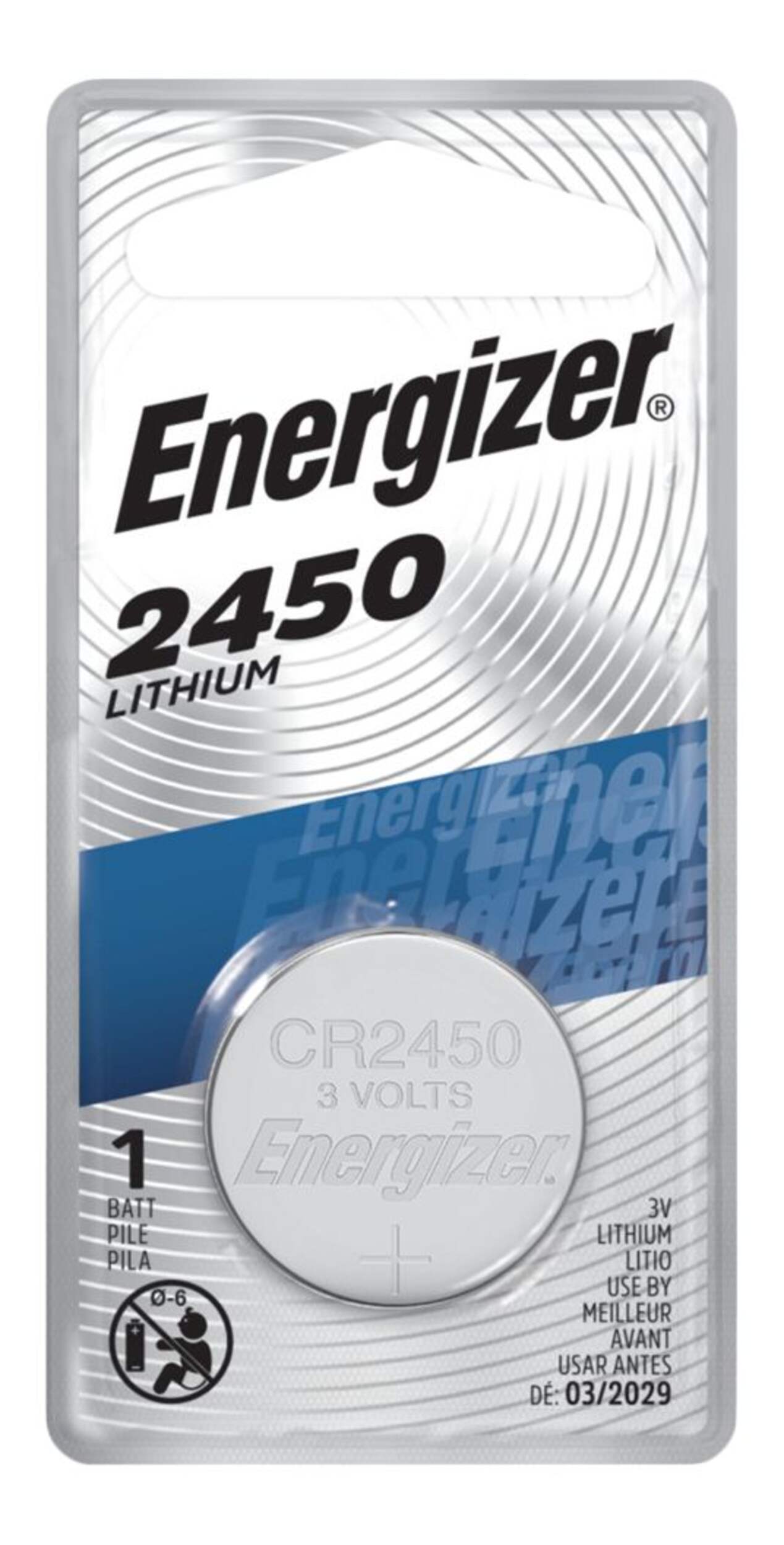

CR2032 vs CR2450 batteries: Which one is better for your device?

Many daily devices use CR2032 and CR2450 batteries because of their small size and reliable performance.

7408 Integrated Circuit: A Classic TTL (transistor-transistor logic) Type IC

The 7408 integrated circuit is a classic TTL (transistor-transistor logic) type IC, which is widely used in various digital circuits. It contains four 2-input AND gates, each with two inputs and one output, for performing logical AND operations.

What is Transistor hFE

hFE, also known as current gain or β (Beta), is an important parameter of the transistor, which represents the ratio between the base current and the collector current. It describes the gain capability of a transistor when amplifying current.

IGBT vs. MOSFET: A Comprehensive Comparison of Features

Both IGBTs and MOSFETs are important semiconductor devices that are widely used in power electronics, switching power supplies, and other high-power control systems. They can both be used to control the flow of current, but their operating principles, characteristics, and application scenarios differ.

WiFi 7 vs WiFi 6: Wireless Network Routing Comparison

WiFi 7 (802.11be) and WiFi 6 (802.11ax) are both wireless network communications standards, but they have significant differences in performance, spectral efficiency, latency, and the number of devices they support.

ENIG vs ENEPIG PCB: Explore the Difference

The choice of PCB surface finish is more than just a detail; it determines the performance and lifespan of the PCB. The versatile and robust Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG) and the reliable and classic Electroless Nickel Immersion Gold (ENIG).

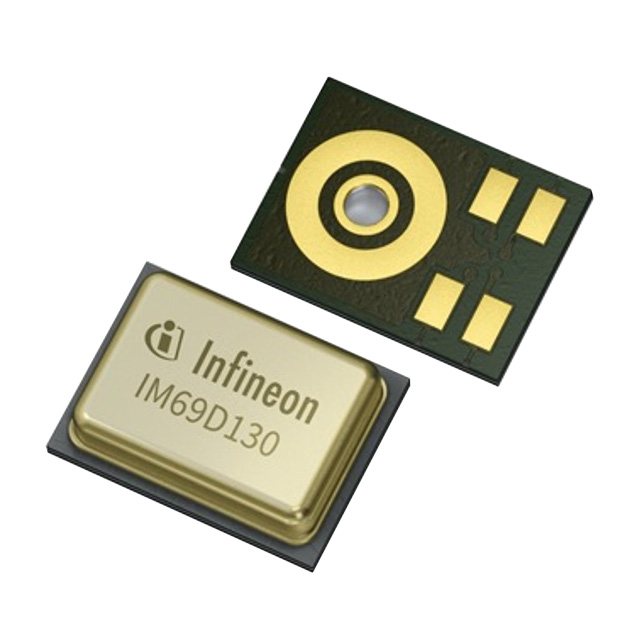

The automotive crystal oscillator FA-238A is the preferred choice for car Bluetooth

Epson FA-238A is a high-performance quartz crystal oscillator widely used in automotive, industrial and consumer electronics fields. It is particularly suitable for automotive-grade and high-reliability applications, with excellent temperature stability, low power consumption and high precision.

What are the differences between tantalum capacitors and ordinary capacitors

Tantalum capacitors are often used in high-precision circuits due to their high reliability, stability and small size, but due to their high price and polarity requirements, special attention should be paid to the connection polarity during design.

What is a clamping diode? Principle, function and application analysis

Clamping diodes are a common electronic component, also known as protection diodes or baropendulum diodes.

Four Common Topological Approaches to Powering LEDs

There are many topologies that can be used to power LEDs. As you probably already know, you need to first identify your design requirements before you start selecting, or you may end up with a design that is less than ideal or, worse, not guaranteed to work properly over the long term.

Regionalization Trend of Global Electronic Component Manufacturing: The Impact of Multinational Joint Ventures and Supply Chain Diversification

As global supply chain pressure increases, more and more electronic component companies are establishing production bases in places such as India and Southeast Asia, promoting the regionalization of supply chains.

US CHIPS Act 2024 in-depth implementation: How to reshape the global semiconductor supply chain and the future of technology

In August 2024, as the CHIPS Act is further promoted, the United States strives to localize the semiconductor industry and reduce external dependence. This strategic transformation is reshaping the global chip supply chain and is crucial to the future development of emerging technology fields such as AI and big data. This article deeply analyzes how the CHIPS Act reshapes the global supply chain and brings key industry impacts.

Hisense TVs sold out in Walmart on Black Friday

During this year's Black Friday promotion, Hisense TVs once again became a hot-selling product in the United States. Recently, a large number of videos of Americans rushing to buy Hisense TVs appeared on social media.

Electronic clock based on STC89C52 single chip microcomputer

Based on STC89C52 single chip microcomputer, it realizes the functions of electronic clock display and adjustment and calendar display and adjustment.

AI drives supply chain management change: achieving a future of proactive decision-making and improved efficiency

The revolutionary role of AI in supply chain management

In the past, artificial intelligence (AI) technology was mainly mastered by a few elites in the technology industry. However, today, AI has become an indispensable tool for companies that want to maintain a competitive advantage in supply chain management.

Traditional supply chain management relies on the operation of functional systems, which are increasingly unable to cope with today's complex and changing global environment. In the past, the passive response mode often only took action when there were delays in goods, insufficient inventory or rising costs. With the popularity of real-time data, this practice is not only inefficient, but may also lead to increased fragility of the supply chain. The introduction of AI enables supply chain management to shift from passive to active, using real-time data to help managers make more informed decisions.

The importance of AI infrastructure

Although AI has shown great potential in supply chain management, companies may miss this opportunity if they do not establish an effective AI infrastructure, such as an integrated data pool and a comprehensive data management platform. Without proper data integration processes, companies will not be able to fully utilize the advantages of AI, thereby limiting their ability to optimize and innovate supply chains. Therefore, companies must first lay a solid foundation to ensure that AI investments can generate accurate and actionable insights to maintain strong risk resilience in the face of global challenges.

Building the right AI infrastructure is challenging but also an important task that companies must face. This not only requires a lot of time and financial investment, but also involves complex technical issues. Many companies give up due to high costs and technical difficulties, or choose incomplete systems, resulting in the inability to obtain deep insights.

The competitive advantage of real-time insights

The power of AI lies in its ability to quickly process large amounts of data and provide real-time information on multiple dimensions such as supplier performance and inventory levels. This enables managers to get clear answers to questions such as "Why should I care about AI?" and "How can it improve my operational efficiency?" AI can not only parse complex multivariate data, but also transform it into actionable information, thereby significantly saving time and costs.

Currently, the supply chain faces unprecedented challenges, such as extreme climate, policy changes, port strikes, and fluctuations in consumer demand. These factors have put higher demands on the flexibility of the supply chain. AI-driven platforms can predict supply chain needs, quickly identify demand changes and supply bottlenecks, and help managers make timely decisions, such as adjusting transportation routes or replanning inventory levels.

In addition, AI enhances scenario planning capabilities, allowing supply chain managers to simulate multiple potential scenarios for different demand fluctuations and supply chain disruptions. For example, what if demand increases by 20% next quarter? How will a 10% drop in supplier reliability affect inventory? These questions can now be answered in a short period of time, helping companies to quickly adjust strategies and ensure business continuity.

Diversity of AI platforms

Not all AI platforms are effective for supply chain management. While predictive analytics has received a lot of attention, it is prescriptive analytics that really drives progress in the supply chain. The tools used by many companies often do not provide real value and lack practical support. Therefore, companies need to look for AI solutions that can provide practical action guides to achieve significant business improvements.

A well-designed AI platform, combined with machine learning technology, can greatly improve decision-making capabilities. However, AI alone is not enough to realize its full potential. The real power lies in combining AI with strategic partnerships to achieve meaningful results. This means achieving real-time process optimization, not just reacting to past events.

Future Outlook

The future of supply chain management lies in developing solutions that can achieve highly autonomous planning, reduce human intervention, and let the system take charge of every link from demand forecasting to execution. While we are not yet fully there, the foundations being laid today will ensure we can take full advantage of these advanced capabilities when the time comes.

In an era where agility and efficiency are key competitive advantages, AI is not only the future of supply chain, but is also reshaping the way supply chain operates today. Companies that actively adopt these technologies will stay ahead in the ever-changing market environment.