Based on the STM32MP157CAA3 teaching pendant solution

What is a teach pendant? A teach pendant is a handheld device used for manual robot manipulation, programming, parameter configuration, and monitoring.

Teach pendant introduction

The teach pendant (FlexPendant), also known as a teaching programming device (hereinafter referred to as a teach pendant), is the core component of a robot control system. It is a device used to register and store mechanical motion or process memory, which is executed by an electronic system or a computer system. Regarding the programming and control technology of industrial robots, there have been many developments and new applications in the past few years, and the teach pendant is one of the components.

The reason why the teach pendant is widely used in the field of industrial robots is inseparable from the following advantages:

1.It has a disable switch to ensure the safety of equipment operation.

2.Monitor the status information of the robot and all equipment in the work unit.

3.Complete the test more conveniently and quickly.

4.The teach pendant can make real-time adjustments to the robot program.

5.The teach pendant can reliably and actively prompt the operator to make the required input.

6.The teach pendant can integrate many components in the work unit.

7.Allow the user to add control logic.

Application scenario

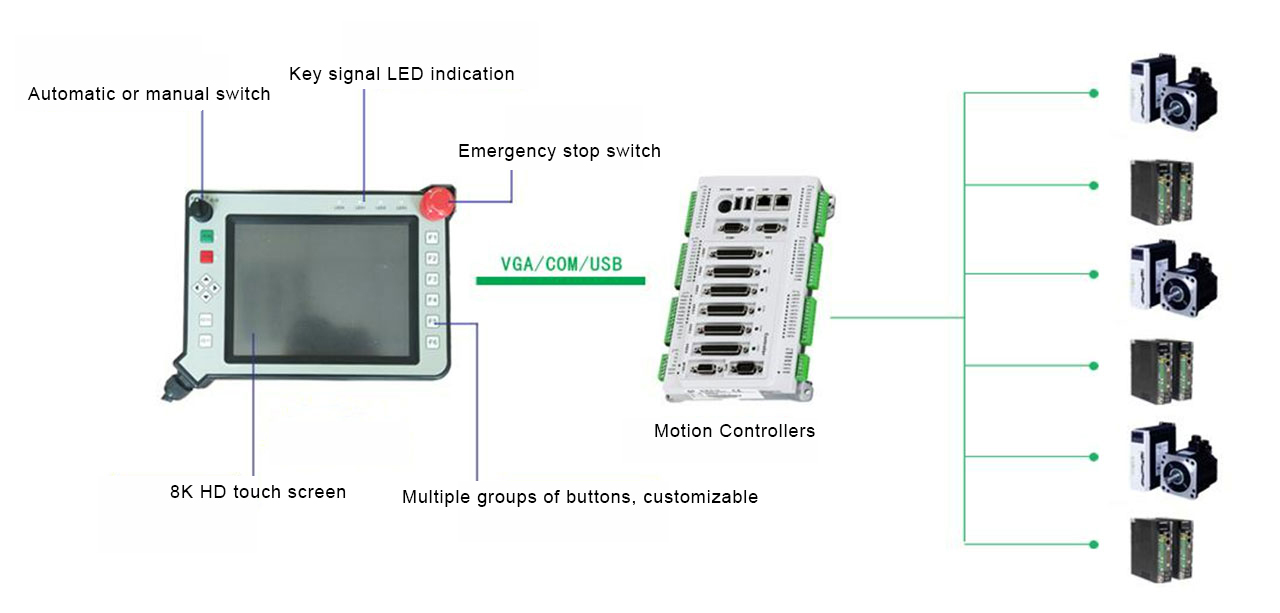

Handheld teach pendant, VGA/COM/USB three-group data connection embedded motion controller. 8-inch HD touch screen Linux interface. Ordinary PC development platform realizes high-performance multi-axis coordinated motion control and high-speed positioning control. Users can easily program the controller and build an automated control system.

Scenario application diagram

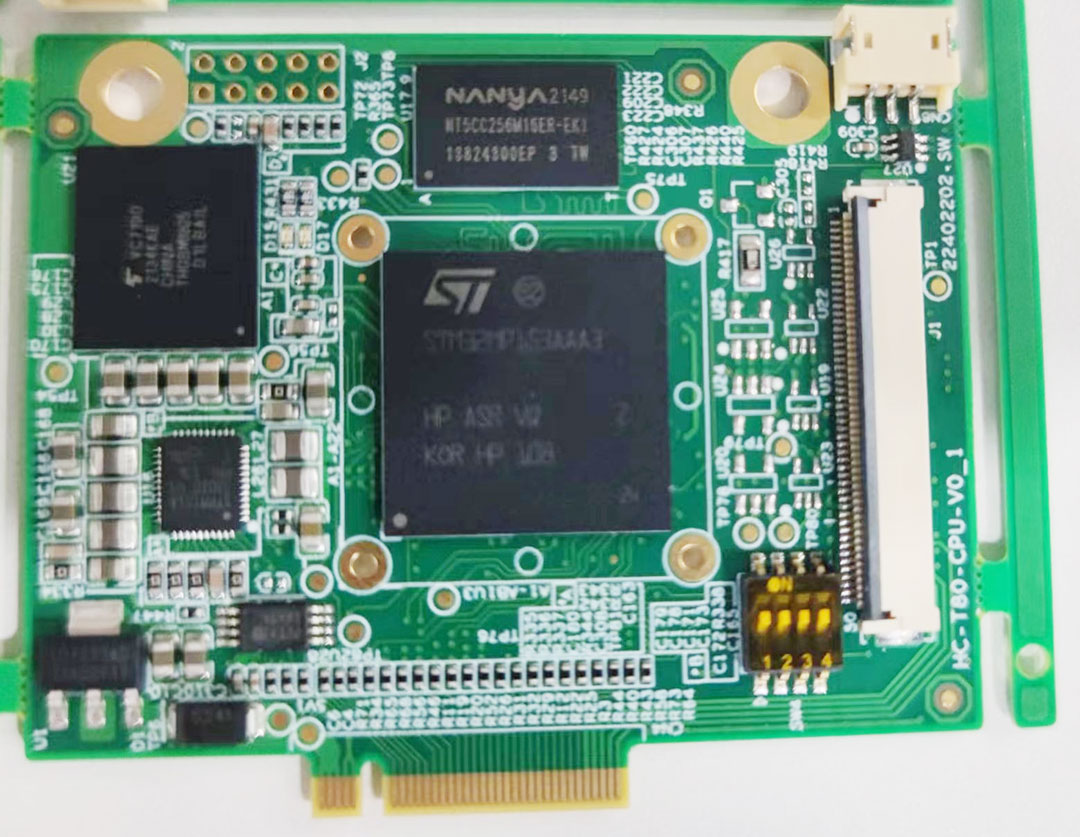

Display board photo

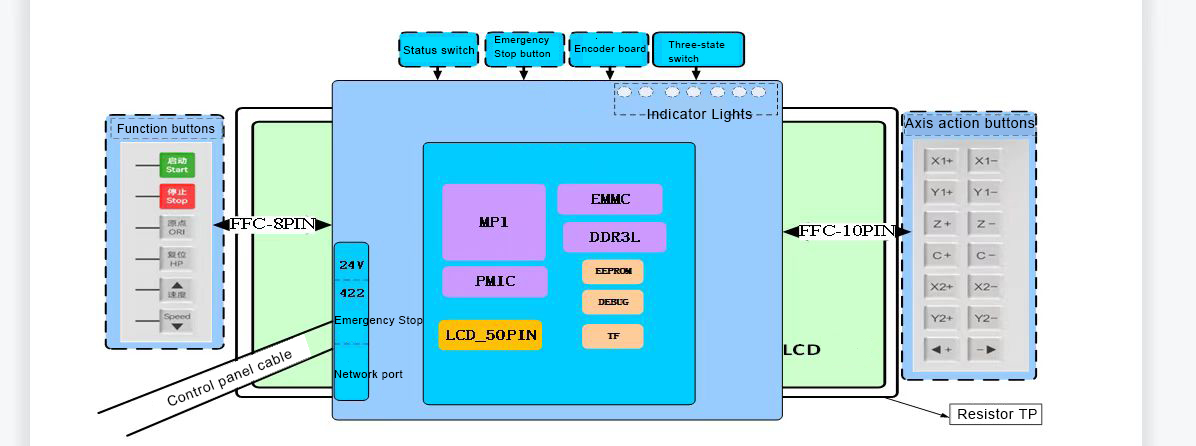

Solution Block Diagram

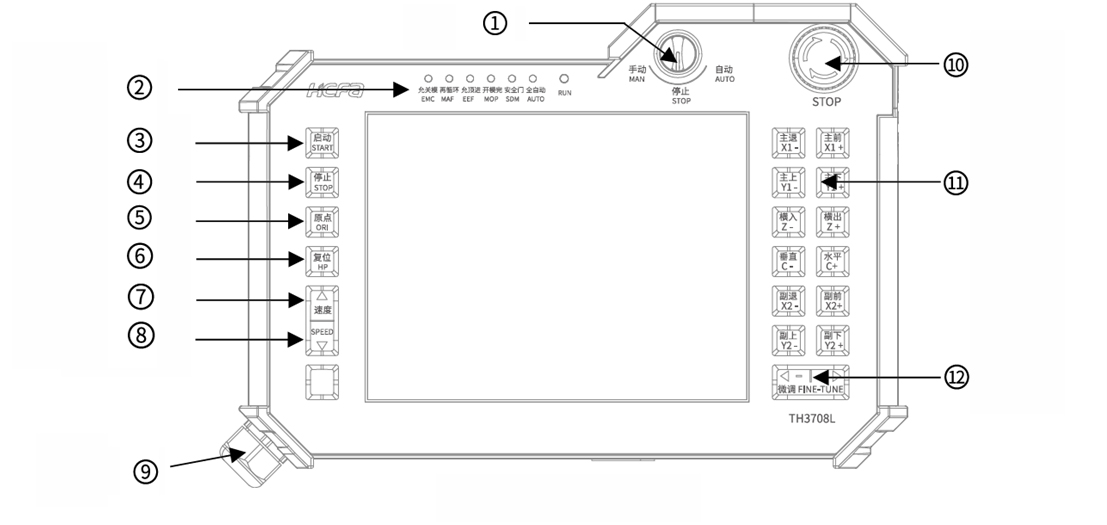

Front view of the parts

Table 1 Front view parts description

| Serial Number | Name | Function |

|---|---|---|

| 1 | three-state switch | The system has three gears in operation: manual (MAN), stop (STOP), and automatic (AUTO). When the system needs to perform a certain operation, turn the knob to the corresponding gear. |

| 2 | status light | There are 7 LED status indicators in total. For details, see the indicator arrangement description. |

| 3 | Function button -Start (START) | When the three-state switch is turned to the automatic position, the system enters the automatic operation screen. Press the start button again to enter the automatic operation working mode |

| 4 | Function button - Stop (STOP) | When the system is in automatic operation mode, press the stop button once to exit the automatic operation mode. When there is an alarm, press the stop button once to clear the corresponding alarm. |

| 5 | Function key - Origin (ORI) | Press the origin button once and the system will return to the origin |

| 6 | Function button - Reset (HP) | When the three-state switch is turned to the automatic position, press the reset button once, the upper and lower axes move to the 0 position, and the other axes move to the standby position. |

| 7 | Function key - Acceleration (△) | Increase global speed when running automatically |

| 8 | Function key - Deceleration (▽) | When running automatically, reduce the global speed |

| 9 | Waterproof plug | Waterproof function |

| 10 | Emergency stop button (STOP) | Emergency stop button: If an abnormal situation occurs during operation or operation, press the emergency stop button and the machine will stop all actions immediately. |

| 11 | Axis action key | There are 6 pairs of 12 buttons in total, see the axis action button description for details |

| 12 | Fine-tuning button (FINE-TUNE) | According to the fine-tuning accuracy, press the fine-tuning button once and the axis will run the corresponding distance. |

Core technology advantages

1. Adopt STM32MP157CAA3 heterogeneous dual-core processor

2. Integrated power management IC STPMIC1APQR

3. Equipped with open source Openlinux operating system

4. LCD touch high-precision 4-wire resistive screen

Solution specifications

1. POWER: DC24V (-15%~+20%) 3.7W

2. USB-A interface, supports U disk import program and firmware upgrade

3. Working temperature 0~55℃

4. Electromagnetic interference EFT 2kV (power supply, signal line)

5. 8-inch LCD 800*600 display